Despite their small size, hose clamps play a vital role across various industries. In oil and gas, they withstand harsh conditions to secure pipelines firmly, while for automotive applications, they stabilize hoses in critical systems. In industrial settings, they meet diverse standards to maintain equipment operation, and in agriculture, their corrosion resistance and low cost help fix irrigation pipelines. Overall, hose clamps serve as essential safeguards for multiple sectors.

Applications

1.Fuel transfer hoses 2.Oil transfer hoses 3.Gas delivery hoses

In the oil and gas industry, hose clamps secure hoses in pipelines and platforms. They meet strict requirements for high temperature/pressure, corrosion, and explosion protection.

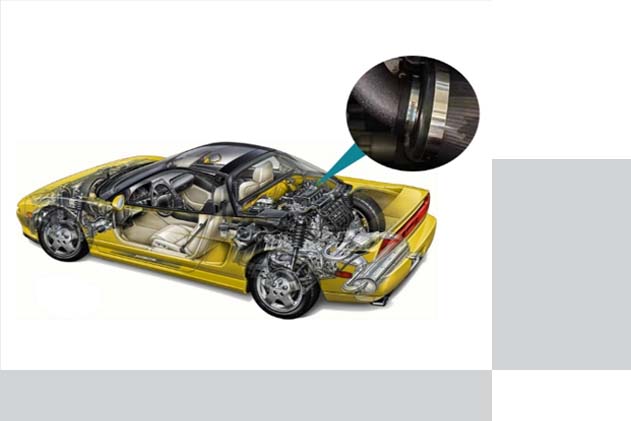

1.Hose clamp for Radiator hoses 2.Hose clamp for Fuel lines 3.Hose clamp for Transmission cooling lines 4.Hose clamp for Air intake hoses 5.Hose clamp for Vacuum hoses 6.Exhaust system connections 7.Turbocharger hoses

In the automotive industry, hose clamps secure hoses in engine systems and fuel lines. They ensure sealing and adapt to vibration and high-temperature conditions.

1.Pneumatic hoses 2.Hydraulic hoses 3.Chemical transfer hoses 4.Water and wastewater hoses 5.Material handling hoses

In the industrial sector, hose clamps secure hydraulic/pneumatic pipes and chemical hoses. They also fit food-grade sanitary pipes, meeting diverse standards for pressure, corrosion, and explosion protection.

1.Watering systems 2.Irrigation hoses 3.Sprayer hoses

In agriculture and irrigation, hose clamps secure irrigation pipes and farm machinery hoses. They feature pesticide corrosion resistance, adaptability to fertilizer-water, and easy maintenance.