Product Description

Specialty

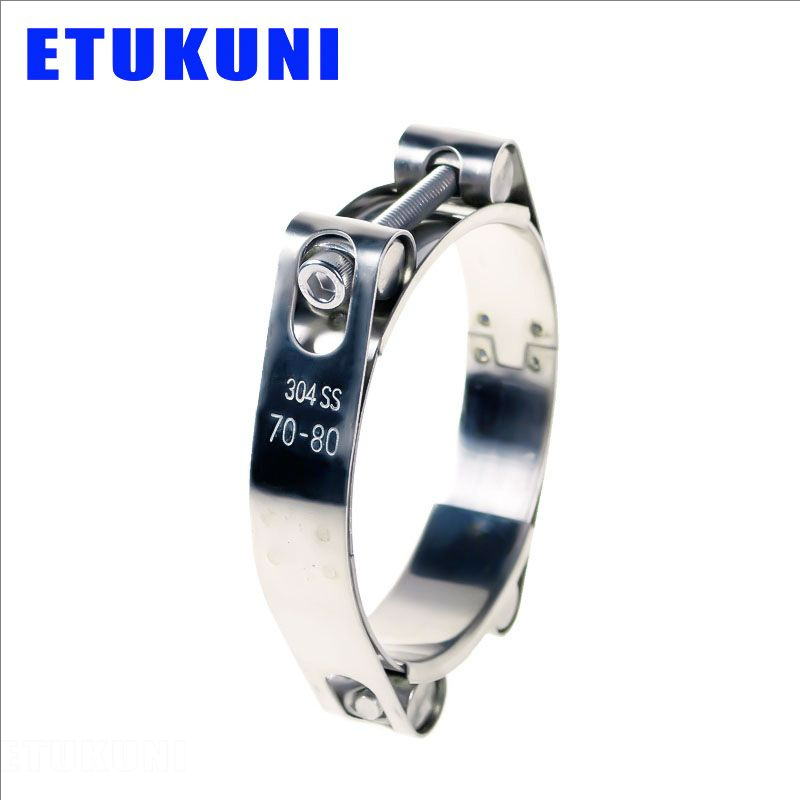

1.Effectively solve the problem of dead corner and liquid and gas leakage during small diameter soft and hard connections.

2.Our robust clamp with solid trunnion hose clamp can meet the ROHS requirement.

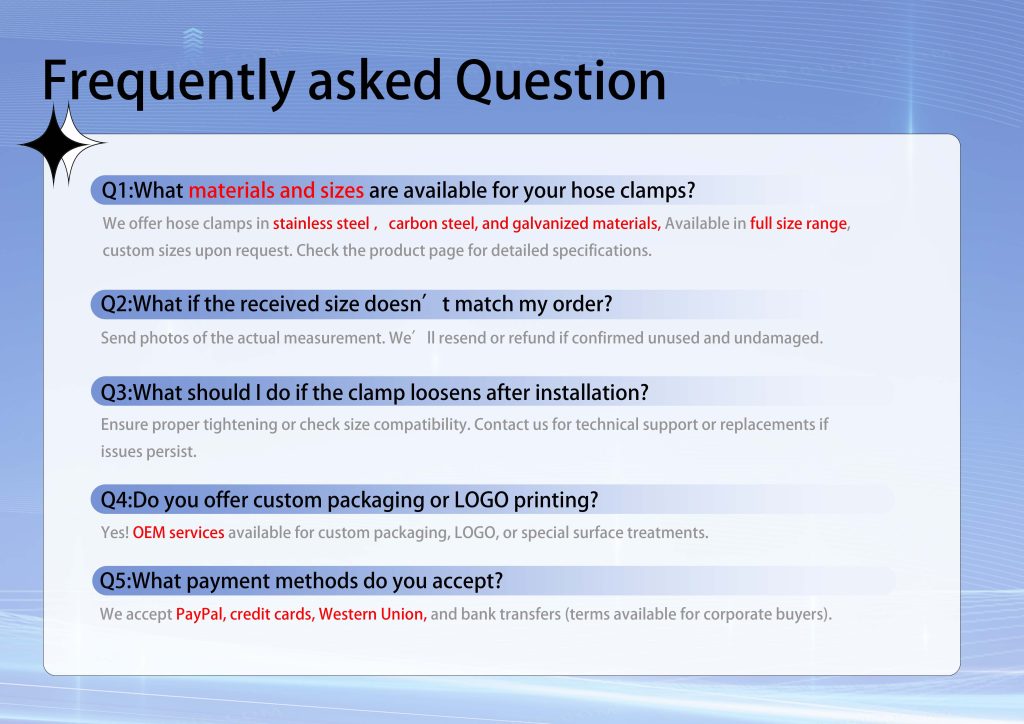

Our service

1. We can provide samples for testing

2. We provide 24/7 customer service

3. We can produce complete the same items based on the client's samples or drawings

4. We offer customization options and we can carve client's logo on the products

5. We always offer good quality at a good price

6. We offer on-time delivery

Product Parameters

| No. | Material | Band | Housing | Screw |

| 1 | W1 | Zinc plated steel | Zinc plated steel | Zinc plated steel |

| 2 | W2 | 201SS | 201SS | Zinc plated steel |

| 3 | 301SS | 301SS | ||

| 4 | 304SS | 304SS | ||

| 5 | W4 | 201SS | 201SS | 201SS |

| 6 | 301SS | 301SS | 301SS | |

| 7 | 304SS | 304SS | 304SS | |

| 8 | W5 | 316SS | 316SS | 316SS |

| No. | Clamping range | Clamping range | W1 | W1/W4 | W2/W4 | Suggested install torque | W4 | pcs/carton |

| (mm) | (inch) | Thickness*width | Bolt size | Thickness*width | Bolt size | |||

| 1 | 17-19 | 3/4 | 0.6*18 | M5*40 | 0.6*18 | 8.5Nm | M5*40 | 250 |

| 2 | 20-22 | 6/7 | 8.5Nm | 250 | ||||

| 3 | 23-25 | 1 | 8.5Nm | 250 | ||||

| 4 | 26-28 | 1 1/9 | 8.5Nm | 250 | ||||

| 5 | 29-31 | 1 2/9 | 0.8*20 | M6*50 | 0.6*20 | 8.5Nm | M6*50 | 200 |

| 6 | 32-35 | 1 3/8 | 8.5Nm | 250 | ||||

| 7 | 36-39 | 1 1/2 | 8.5Nm | 250 | ||||

| 8 | 40-43 | 1 2/3 | 8.5Nm | 250 | ||||

| 9 | 44-47 | 1 6/7 | 1.2*22 | M6*55 | 0.6*22 | 8.5Nm | M6*60 | 100 |

| 10 | 48-51 | 2 | 8.5Nm | 100 | ||||

| 11 | 52-55 | 2 1/6 | 8.5Nm | 100 | ||||

| 12 | 56-59 | 2 1/3 | 8.5Nm | 100 | ||||

| 13 | 60-63 | 2 1/2 | 8.5Nm | 100 | ||||

| 14 | 64-67 | 2 2/3 | 8.5Nm | 100 | ||||

| 15 | 68-73 | 2 7/8 | 1.5*24 | M8*70 | 0.8*24 | 8.5Nm | M8*70 | 100 |

| 16 | 74-79 | 3 1/9 | 8.5Nm | 100 | ||||

| 17 | 80-85 | 3 1/3 | 8.5Nm | 100 | ||||

| 18 | 86-91 | 3 4/7 | 8.5Nm | 100 | ||||

| 19 | 92-97 | 3 5/6 | 8.5Nm | 100 | ||||

| 20 | 98-103 | 1 5/9 | M8*75 | 8.5Nm | M8*80 | 50 | ||

| 21 | 104-112 | 4 2/5 | 8.5Nm | 50 | ||||

| 22 | 113-121 | 4 3/4 | 8.5Nm | 50 | ||||

| 23 | 122-130 | 5 1/8 | 8.5Nm | 50 | ||||

| 24 | 131-139 | 5 1/2 | 1.7*26 | M10*85 | 1.0*26 | 8.5Nm | M10*90 | 50 |

| 25 | 140-148 | 5 5/6 | 8.5Nm | 50 | ||||

| 26 | 149-161 | 6 1/3 | 8.5Nm | 50 | ||||

| 27 | 162-174 | 6 6/7 | 8.5Nm | 50 | ||||

| 28 | 175-187 | 7 1/3 | M10*100 | 8.5Nm | M10*100 | 50 | ||

| 29 | 188-200 | 7 7/8 | 8.5Nm | 25 | ||||

| 30 | 201-213 | 8 2/5 | 8.5Nm | 25 | ||||

| 31 | 214-226 | 8 8/9 | 8.5Nm | 25 | ||||

| 32 | 227-239 | 9 2/5 | 8.5Nm | 25 | ||||

| 33 | 240-252 | 10 | 8.5Nm | 25 |