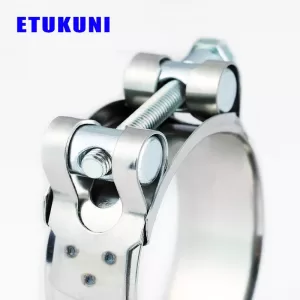

Product Description

We offer a variety of hose clamps, including Single Bolt Hose Clamp and Single Bolt Hollow Hose Clamp.

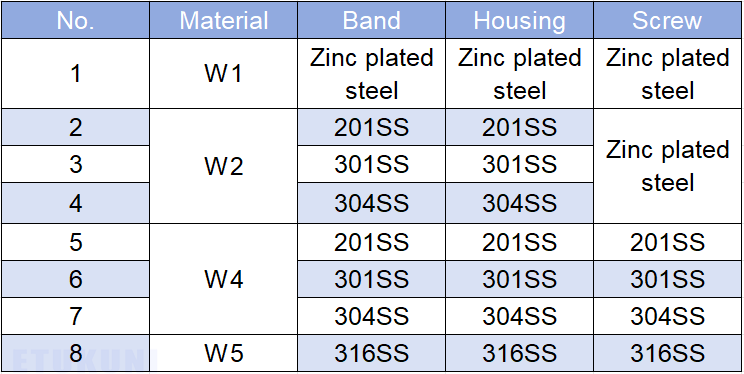

Material:

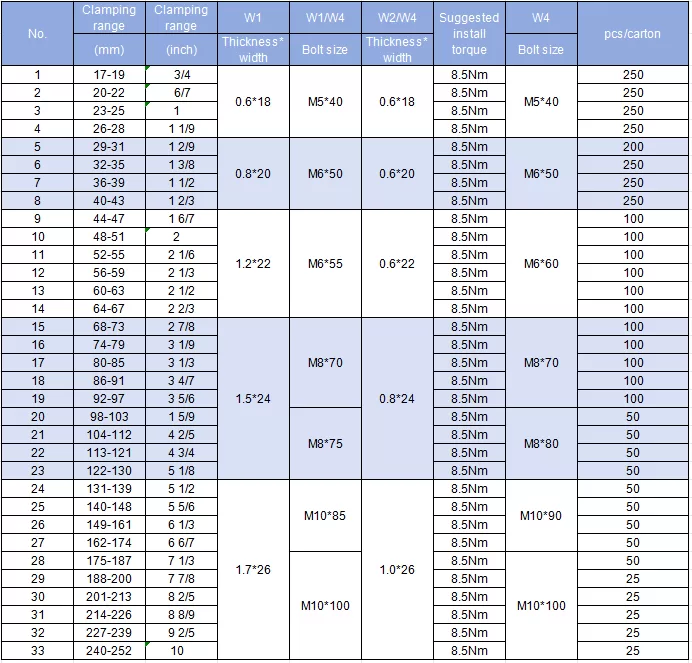

Single Bolt Hose Clamp:

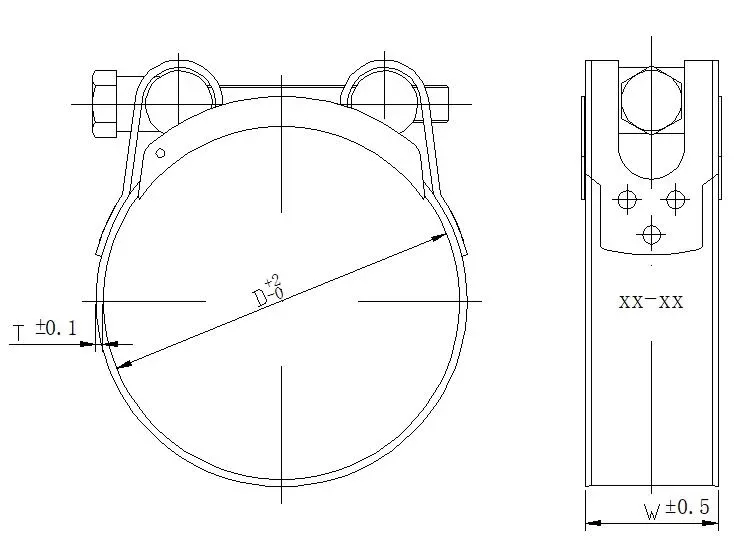

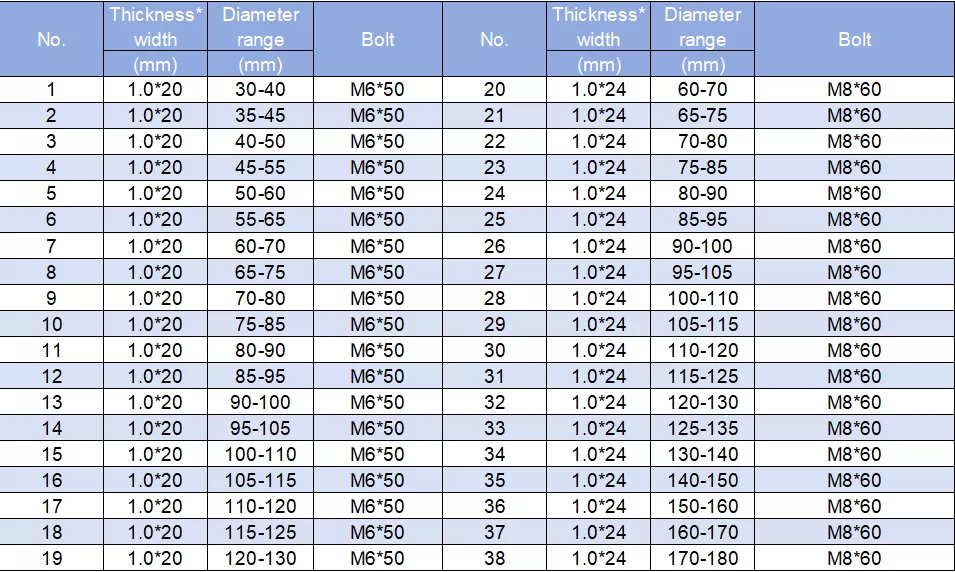

Single Bolt Hollow Hose Clamp

Specialty :

Upgrade your hose connections with our Heavy Duty Single Bolt Hose Clamp, engineered to deliver unmatched durability, corrosion resistance, and effortless installation in demanding environments. These heavy duty hose clamps feature a reinforced stainless steel or galvanized steel construction with a precision-polished surface, ensuring a leak-proof grip while protecting hoses from abrasion, vibration, and extreme pressures in automotive, marine, or industrial applications.