What is Heavy-Duty Hose Clamps

Heavy-duty hose clamps include single-head heavy-duty clamps, double-head solid heavy-duty clamps, and T-type heavy-duty clamps. Also known as European-style clamps, they generally refer to single-head solid heavy-duty clamps. Their commonly used bandwidth sizes are 20mm, 24mm, 26mm, etc. These clamps are relatively large in size and generate strong torque, which is why they find wide use in scenarios that demand high clamping force.

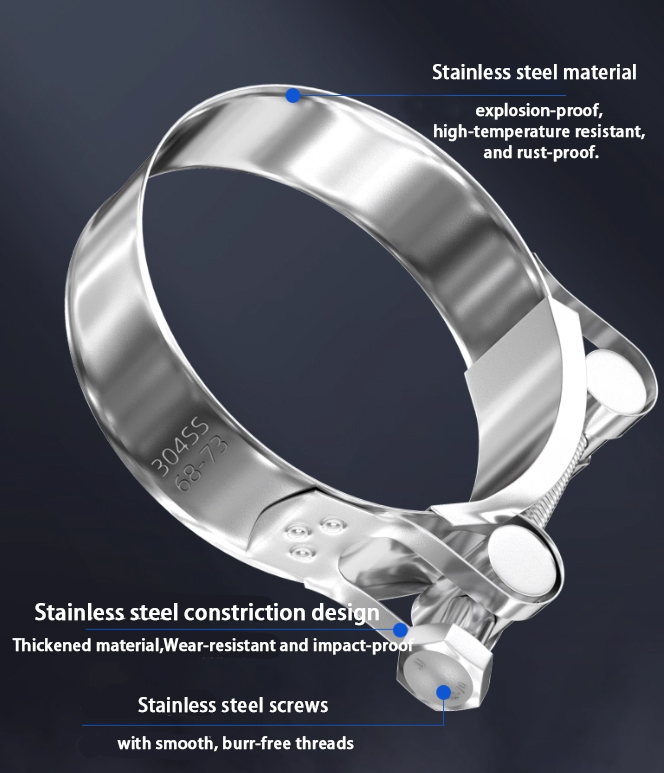

Advantages

- You can choose heavy-duty hose clamps in various materials, such as electroplated carbon steel and stainless steel.

- They adopt projection welding for connection, which gives them an ultra-strong structure; additionally, the edges of the steel strips protrude outward to protect the surface of hoses.

- The clamp’s through-panel connection design ensures excellent sealing performance.

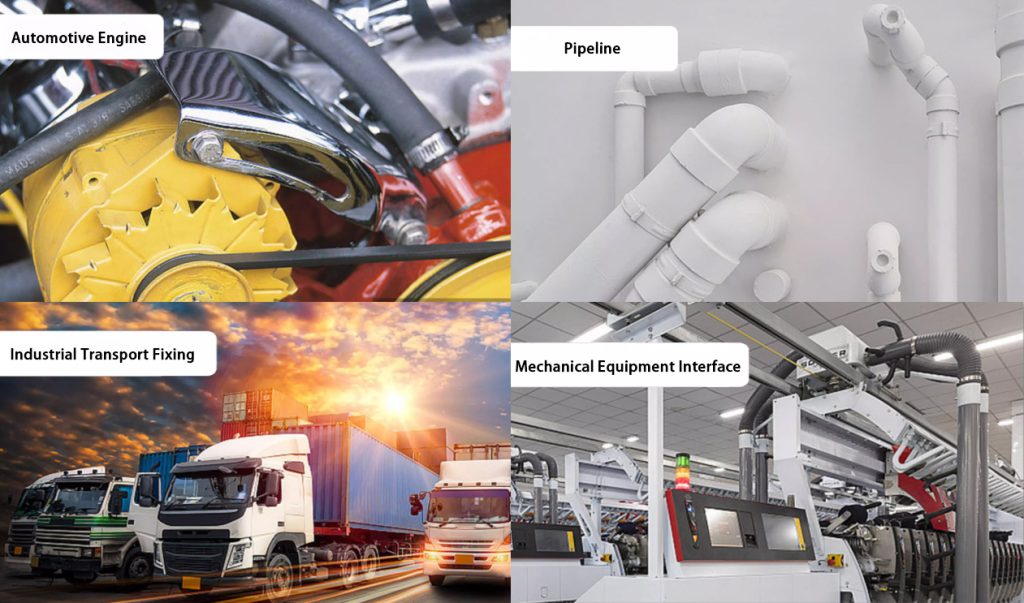

Applications

This type of heavy-duty hose clamp mainly connects rigid and flexible pipes—specifically those that need extremely secure fastening or have thick walls. What’s more, people commonly use it for automotive oil pipes, carburetors, and engines in practical applications. Once properly installed, the clamp has an extremely low risk of loosening during use.

Moreover, heavy-duty hose clamps effectively solve the problems of dead corners and leakage of liquids or gases that occur when connecting small-diameter rigid and flexible pipes. They feature a simple structure and easy manufacturing, with a cost only 30% of that of original products. For these critical reasons, industries actively deploy these components as essential support elements in machinery. You will consistently find them performing reliably in motor vehicles, petrochemical plants, and pharmaceutical manufacturing. Furthermore, their application extends to food and beverage brewing, sewage treatment, dust collection systems, as well as various automotive parts.

Usage Instructions

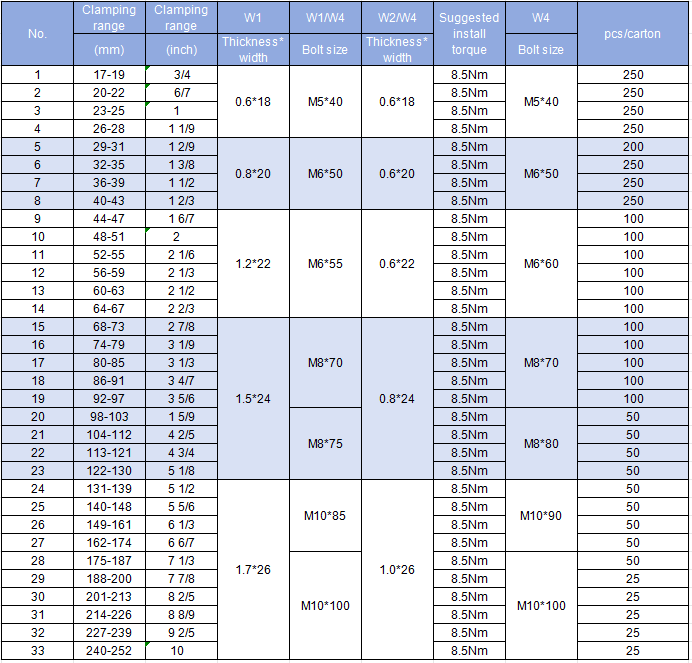

Single-head heavy-duty hose clamps feature a narrow adjustment range of just 5mm. Therefore, careful selection is essential to prevent two common issues: either the clamp fails to slide over the pipe, or if it does, it remains loose even when fully tightened.Instead, you should first confirm the final installation diameter of the hose. For example, if the maximum outer diameter of the connected rigid and flexible pipes is 54mm, check the specification table—you will find a clamp size of 52-55mm, which includes 54mm. This is the correct specification you should choose.

ETUKUNI is committed to providing customers with high-quality, reasonably priced heavy-duty hose clamps. We always center our efforts on customer needs and are dedicated to offering you reliable solutions.

If you need to learn about specific product prices and minimum order quantities (MOQ), please feel free to contact us at any time to get a free quote.