Introduction

Hose clamps are essential components in various industries and applications, ensuring secure connections and preventing leaks. This guide aims to provide an in-depth understanding of hose clamps, their uses, types, applications, installation, removal, measurement, and materials. This information will be valuable for professionals and DIY enthusiasts alike.

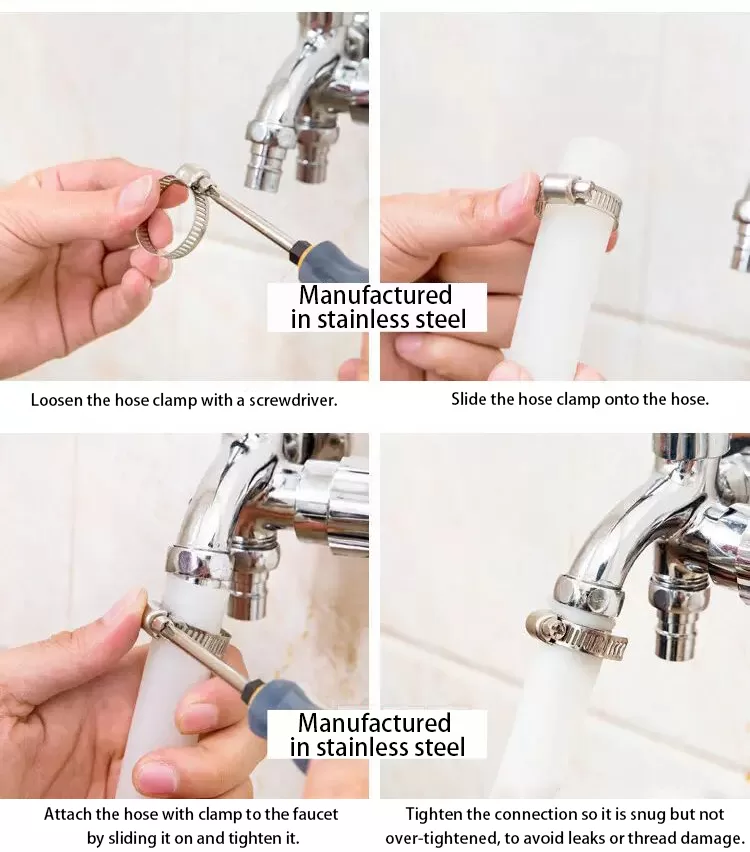

Uses of Hose Clamps

Hose clamps are primarily used to secure a hose over a fitting, such as a spigot or barb, creating a seal that prevents fluid from leaking at the connection point. They also serve to stabilize the hose connection. Common industries that utilize hose clamps include plumbing and automotive, but they are also other applications to prevent leaks during the transport of liquids, chemicals, and gases.

Hose Clamp Selection and Maintenance Tips

In addition to understanding the different types of hose clamps, their applications, and installation procedures, it's essential to know how to select the right clamp for the job and maintain it for optimal performance. Here are some tips to help you choose and maintain hose clamps effectively:

Selection Tips:

Consider the hose material: Different hose materials (such as rubber, plastic, or silicone) may require different types of clamps. Be aware of the hose material's properties and choose a clamp that won't cause damage or fail to provide a proper seal.

Match the clamp size to the hose diameter: As discussed earlier, measuring the outer diameter (O.D.) of the hose is crucial to selecting the correct clamp size. Make sure to choose a clamp that fits within the suggested adjustment range for the best fit and performance.

Take note of the working environment: Hose clamps may be exposed to various environmental factors, such as temperature, moisture, and chemicals. Choose a clamp material (carbon steel, stainless steel, or plastic) that can withstand these conditions without corroding or weakening.

Maintenance Tips:

Regular inspection: Periodically inspect hose clamps for signs of wear, corrosion, or damage. This can help you identify issues early and replace the clamp before it fails.

Proper tightening: Over-tightening a hose clamp can cause damage to the hose and clamp itself, leading to potential leaks or failures. Make sure to follow the manufacturer's torque specifications and use the appropriate tools for tightening.

Replace worn or damaged clamps: If you notice any signs of wear, corrosion, or damage on a hose clamp during inspection, replace it immediately to avoid potential leaks or failures.

Keep spare clamps on hand: Having a few extra hose clamps in various sizes can be beneficial in case of emergencies or unexpected maintenance needs.

In conclusion, understanding the different types of hose clamps, their applications, installation, and removal procedures, as well as proper selection and maintenance, are essential for ensuring the reliability and efficiency of your hose connections. By following the tips and guidelines provided in this guide, you can ensure that your hose clamps perform optimally, preventing leaks and maintaining a secure connection in various applications.

We manufacture various high-quality hose clamps that have earned the trust of hundreds of clients. We welcome you to contact us for a free consultation.