Product Description

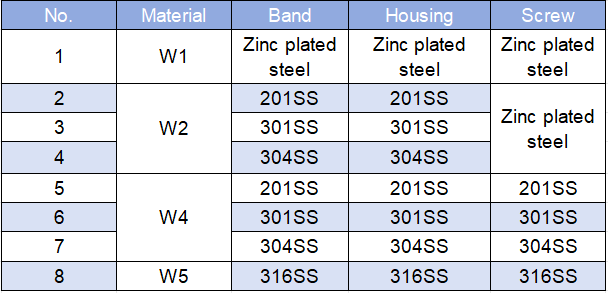

Material:

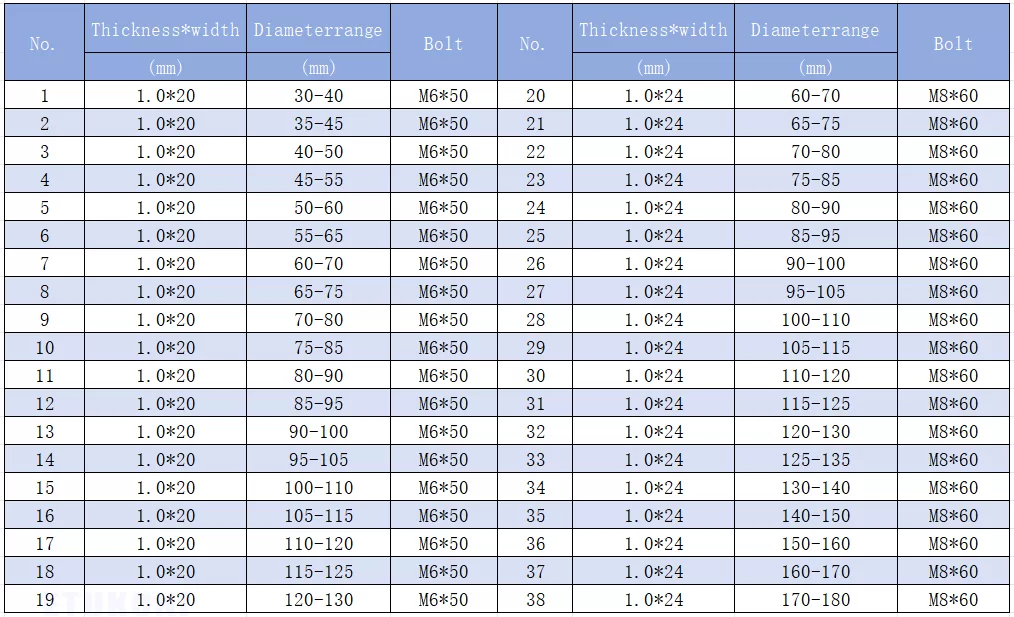

Product Parameters:

Speciality:

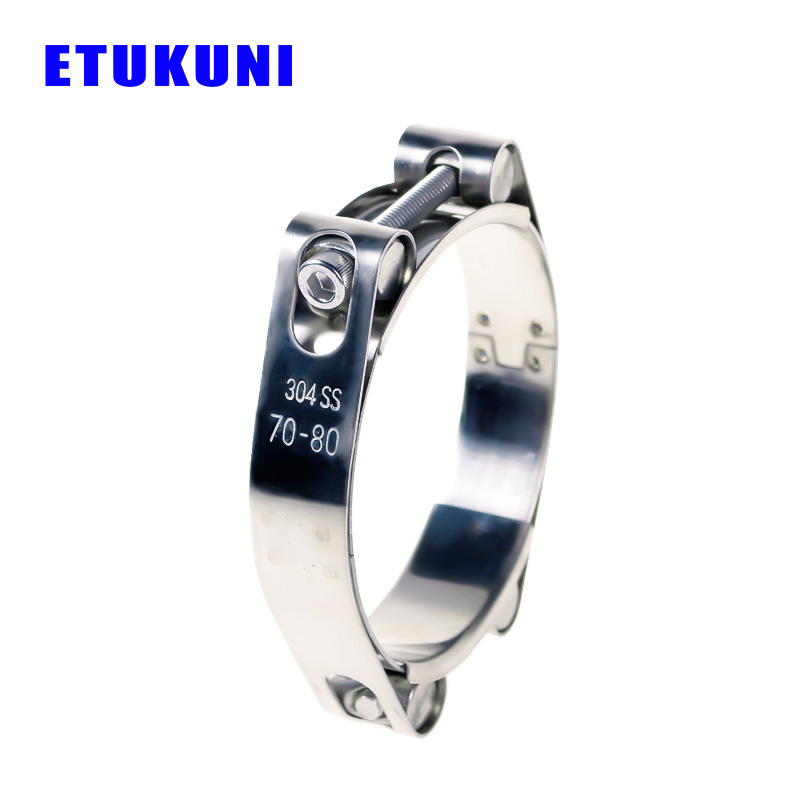

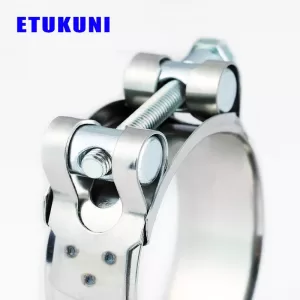

Dual-Bolt Reinforcement: Thanks to its double-bolt design, this clamp evenly distributes force while delivering 40% more consistent tension than single-bolt alternatives. As a result, it's perfect for high-pressure systems reaching up to 700 PSI.

Premium Materials: We construct these clamps using 316 stainless steel or hot-dip galvanized steel, so they resist rust, chemicals, and saltwater with ease. That’s why they’re ideal for offshore or chemical processing environments.

Non-Slip Grip: The laser-polished inner bands and rounded edges protect hoses, while the toothed ridges ensure a secure hold—preventing slippage under pressure.

Easy Installation: With pre-drilled holes and hex-nut bolts, you can tighten them quickly using standard wrenches. In fact, industrial applications see a 20% reduction in assembly time.